Have you found

what you're looking for?

Contact our team of experts

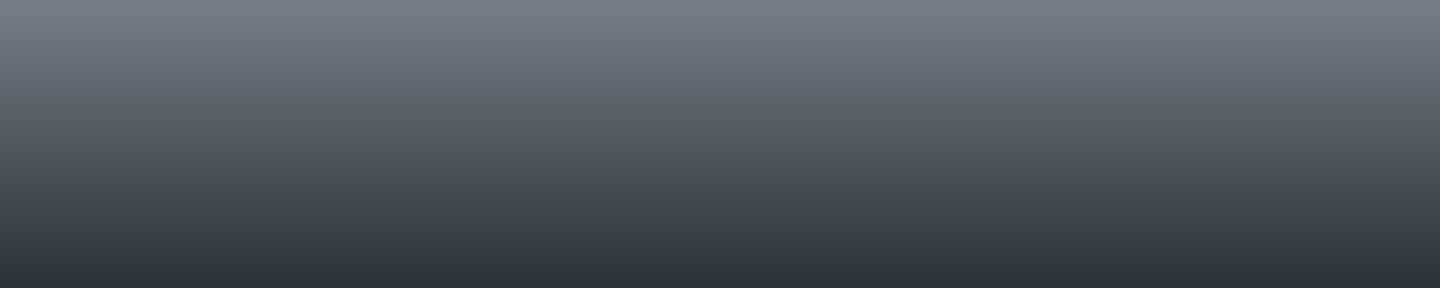

Forécreu has set up an industrial process that is unique in the world for the manufacture of steel, titanium and polymer hole bars. Our two French plants apply this process, renowned for its reliability and manufacturing quality. Cutting, turning, drilling… more than 30 steps are required, from receipt of the raw material to shipment to our customers worldwide, including numerous inspection steps.

Reduction in bar diameter by passing through a die without prior heating.

Reduction in diameter of the heated bar by passing through a die.

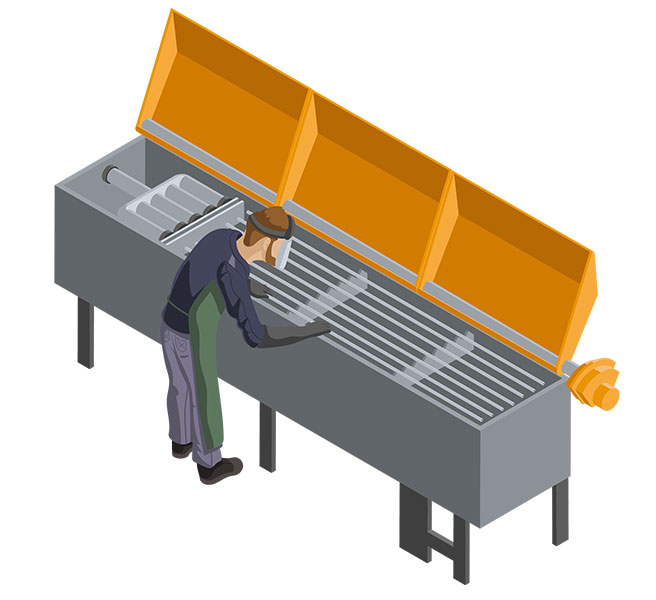

Removal of residues from hole surfaces by chemical pickling.

Verification of final customer geometric conformity.

Correction of outside diameter to customer requirements.

Discover the other steps of the Forécreu industrial process.

Phase 1 – From raw material reception to extrusion

Phase 2 – From geometric inspection to rolling.

Phase 4 – Twisting to customer shipment

Forts d’une expertise de plus de 70 ans, nous sommes fiers de vous présenter notre large gamme de produits et de services destinée aux applications les plus exigeantes.

Contact our team of experts