Have you found

what you're looking for?

Contact our team of experts

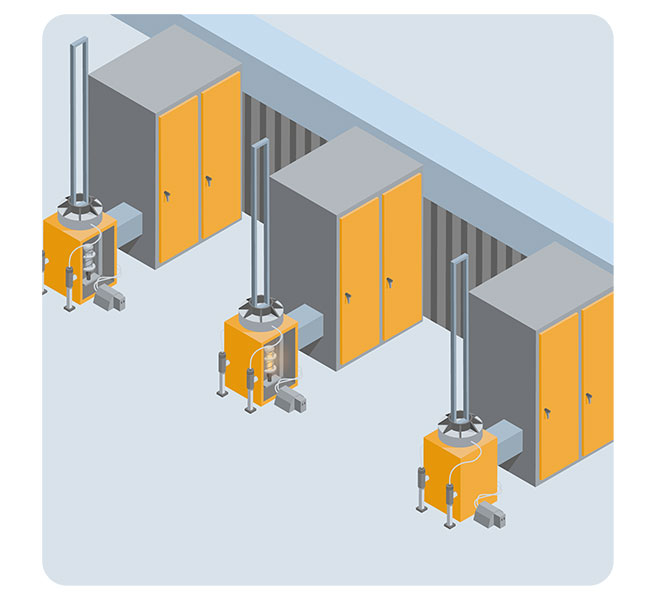

Forécreu has set up an industrial process that is unique in the world for the manufacture of steel, titanium and polymer hole bars. Our two French plants apply this process, renowned for its reliability and manufacturing quality. Cutting, turning, drilling… more than 30 steps are required, from receipt of the raw material to shipment to our customers worldwide, including numerous inspection steps.

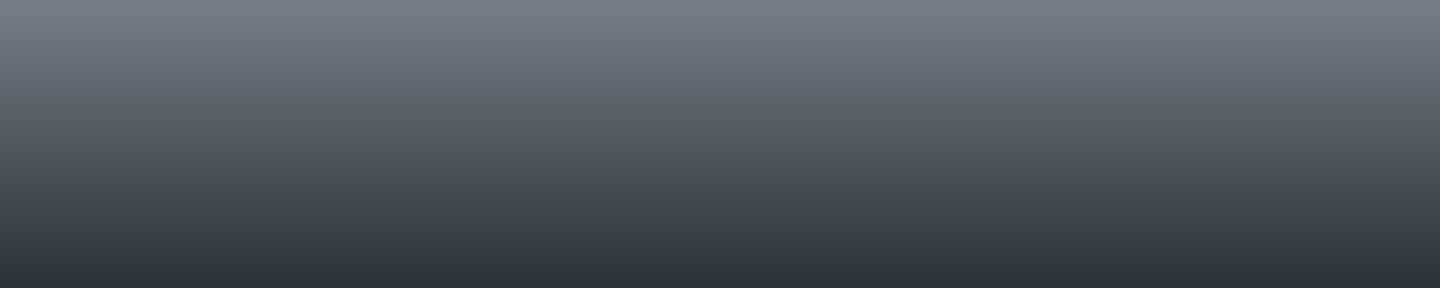

Control of raw material compliance against purchasing requirements

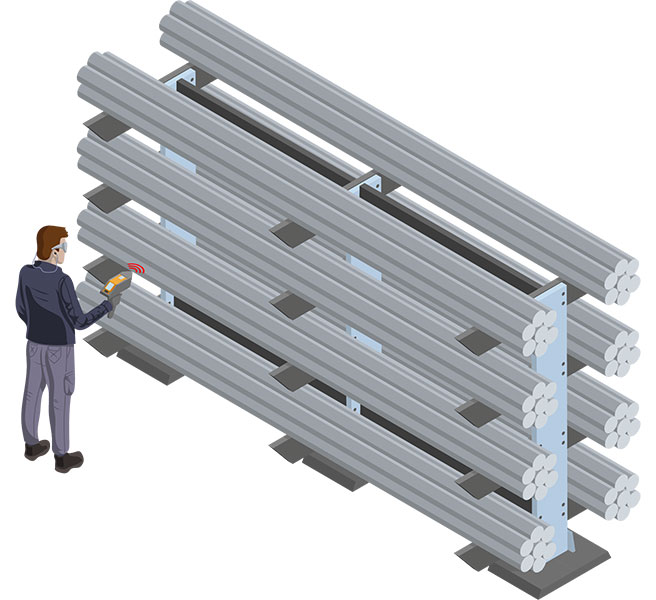

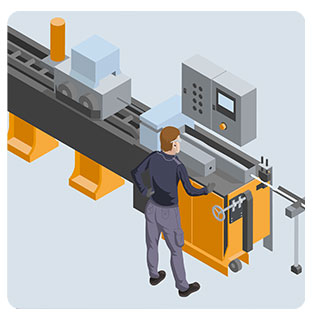

Cut the billet to length to meet customer requirements. Length and diameter determine the number of bars at the end of the process.

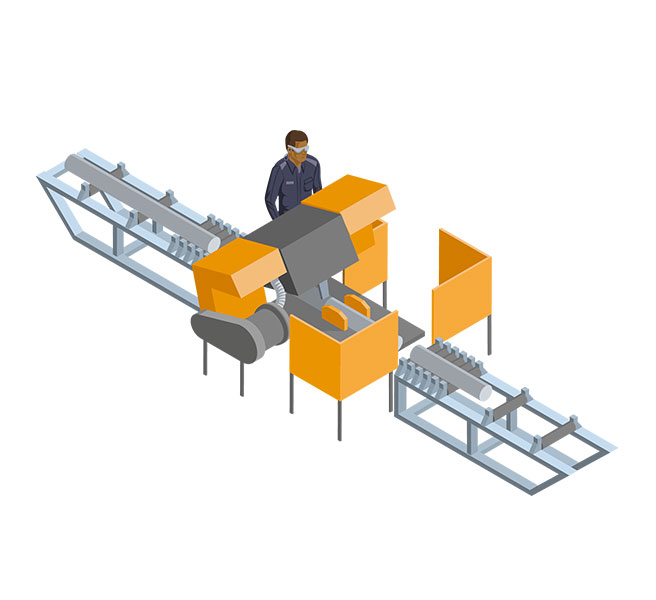

Machining the 1st end. Preparation to ensure good material engagement for extrusion.

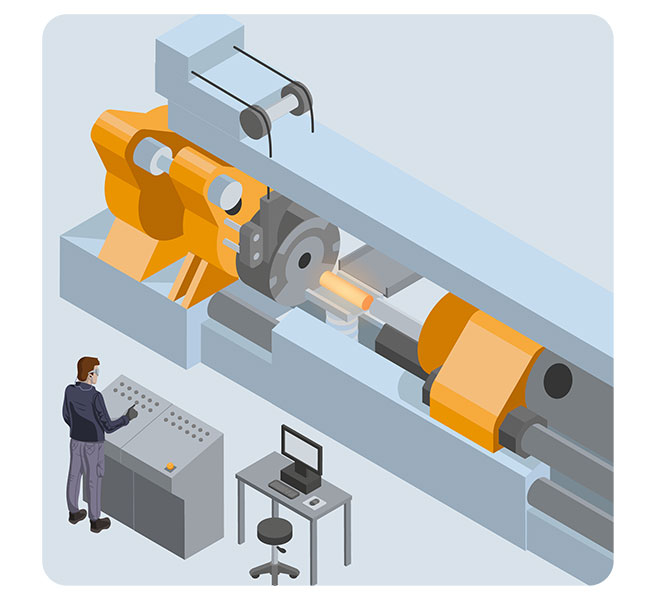

Heating to the temperature required to deform the material.

Transformation of a billet into a bar using a die.

Discover the other steps of the Forécreu industrial process.

Phase 2 – From geometric inspection to rolling.

Phase 3 – From cold drawing to fiberscope inspection

Phase 4 – Twisting to customer shipment

With over 70 years’ experience, we have perfected our production methods and organization to meet your needs and expectations.

Contact our team of experts